Expanding foam

Contents |

[edit] Introduction

Sealants are typically used to close openings between spaces that are too small for other materials such as concrete, timber or mortar to be used. They have a wide range of properties in terms of strength, flexibility, appearance permanence, solubility, corrosion resistance and so on.

Expanding foam filler is a common type of polyurethane filler. It can be sprayed into gaps such as those around windows and doors to stop draughts, fill gaps and dampen sound. It is designed to adhere to a variety of common building materials and can be water resistant.

[edit] Expanding foam characteristics

Foams can be divided into two different ways: type and purpose.

- Type of application: handheld dispenser or gun grade applicator.

- Purpose of application: Filling voids or securing materials through adhesion (these foams have a lower expansion rate).

Expanding foam filler is made up of materials that expand under different conditions, depending on its composition. One type of expanding polyurethane foam requires moisture in order to expand, which can make it sticky during the installation process. Another begins to expand when two different chemicals are mixed together. Dampening the surface that will be treated can help the foam set more quickly.

There are several differences between types of foam which should be clearly marked on the containers:

- Indoor or outdoor use.

- Sandable or paintable.

- Presence of HCFCs or CFCs (no longer permitted).

- Gun grade or handheld.

[edit] Possible dangers of expanding foam

It’s important to proceed with caution with the application process, since the chemicals can be toxic if they are not used properly. However, the substance should be safe once it has fully expanded and dried.

Basic foams can be flammable and may create toxic smoke if they are exposed to fire. There are some foams that can resist fire for a certain time when directly exposed to flames.

Cured foam should be protected from daylight or other light since this can degrade the effectiveness of the product over time. Dried foam can be painted, or otherwise covered, to protect it from light.

Expanding foam should be used relatively quickly once a can or gun is started, since the chemicals may not retain their effectiveness over time. It can also be difficult to remove or clean foam. There is a special type of chemical that can be used to clean wet foam, and in some instances, acetone can be used.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

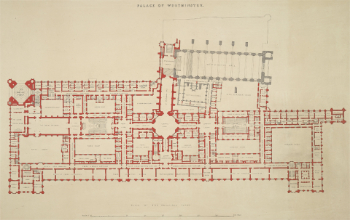

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.